REBUILD & REFRESH

Refresh: Get rid of corrosion across bodywork

2007 Land Rover Defender Refresh

On this occasion the customer got in touch with us regarding some spots of corrosion around the vehicle that he was unhappy with. Some on the bulkhead, windscreen frame, rear tail panels, cappings & rear cross member.

However, upon inspection a lot more corrosion was found. The front seat box ends were badly corroded, and when removing the rear carpet & seats to lift the roof to replace the cappings the technician found the most badly corroded rear tub he had ever seen on a Puma Defender.

With the customers authorisation we then proceeded to replace the entire rear tub, using galvanised steel parts where possible in order to ensure longevity & seal/bond all panels into place.

Along with mechanical repairs, an MOT & service our Specialist Technician Pete with 36 years of experience spent 204 hours giving this Defender a loving refresh.

Work completed February 2023

Before

Before

Before

Bulkhead, windscreen frame & windscreen block corrosion

Bulkhead, windscreen frame & windscreen block corrosion

Headlight rings corroded

Corrosion on cappings

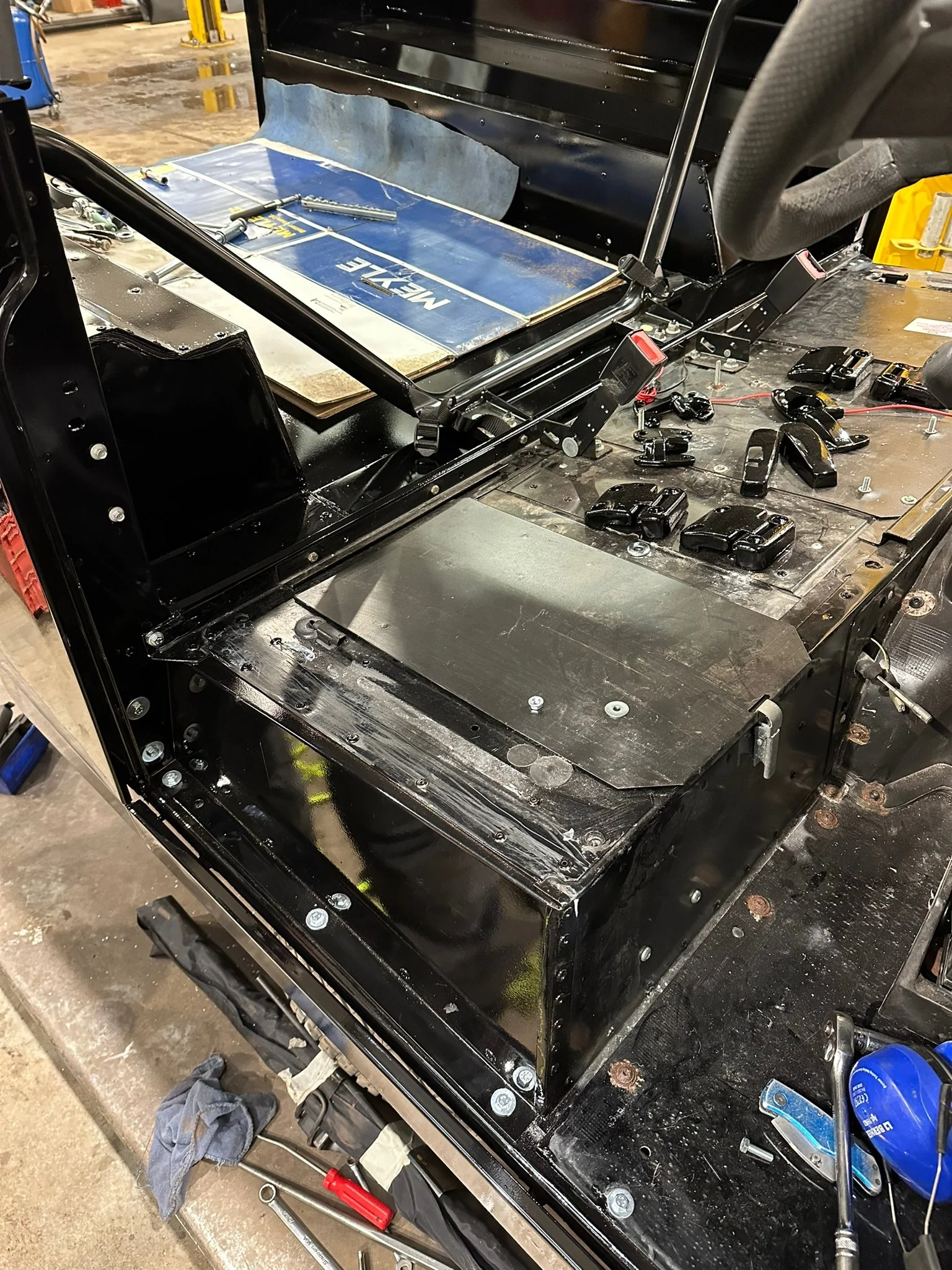

Vehicle strip down in progress, roof, windscreen frame, cappings, doors, rear seats & carpet removed.

Drivers side rear tub bench removed, a lot of corrosion can be seen here

Seat box ends corroded & holed.

Seat box end panel removed

Corrosion can be seen around bulkhead removal bar mounts

Corrosion under bulkhead removal bar plate

Rear seat bracket corrosion

Corrosion on rear tail panel

Corrosion on bulkhead.

Corrosion cleaned off of bulkhead.

Drivers side bulkhead corrosion cleaned off

Drivers door prepped for paint

Rear tub removed, floor & supports next

Rear end bodywork removed

Bulkhead prepared for priming then painting

Rear tub panels being bonded together to prevent any water ingress.

New rear tub supports in galvanised steel, this will provide a much longer life span than the originals. With full rebuilt rear tub benches.

Starting to rebuild. New threshold panel fitted

Tub crossbearers corroded

Rear tub cross bearers cleaned and painted, support rails to be done.

Rear cross member corrosion cleaned off.

Passenger side quarter panel bonded & secured on

New panels bonded & secured into place

Rear tail panel bonded on, excess to be cleaned off

New quarter panel & supporting panels fitted

Rear tub floor replaced, quarter & tail panels fitted.

Quarter & tail panels fitted, front doors also temporarily fitted in order to align these panels properly

New panels and rear crossmember primed

New panels and rear crossmember primed

Rear quarter panels primed

Bulkhead primed

Bulkhead primed

Seat box end panel painted, hinges painted

Rear tub painted

Rear end painted, and part reassembled

Rear end painted

Finished vehicle

New Strathearn Engineering logo design on a spare wheel cover.

Finished job

Rear end finished, showing off the new Strathearn Engineering logo wheel cover

Customer opted for a new wheel cover showing our older logo